Precision nanoindenter

G200X

1. Easy to use and user-friendly

2. Mechanical test at the nanometric scale

3. Precise quantitative results

4. Large variety of sample

The Nano Indenter G200X provides an easy-to-use nanoscale mechanical tester that quickly delivers accurate, quantitative results. The G200X system handles a wide variety of samples from hard coatings to soft polymers and offers the most comprehensive test suite available in the KLA Instruments nanoindenter product line.

Applications of nanoindentation

- High speed hardness and modulus measurements (Oliver-Pharr)

- High speed material properties maps

- ISO 14577 hardness test

- Interfacial adhesion measurement

- Measurement of fracture toughness Measurement of viscoelastic properties, including the tanning delta and the storage and loss module

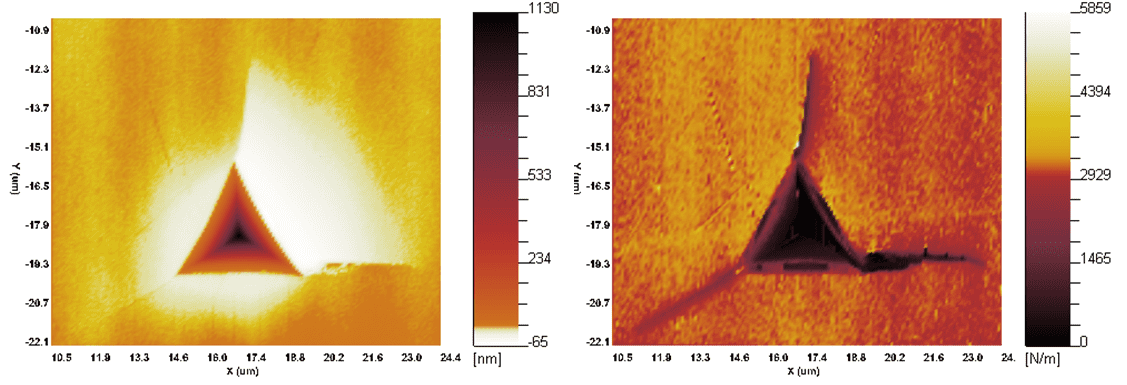

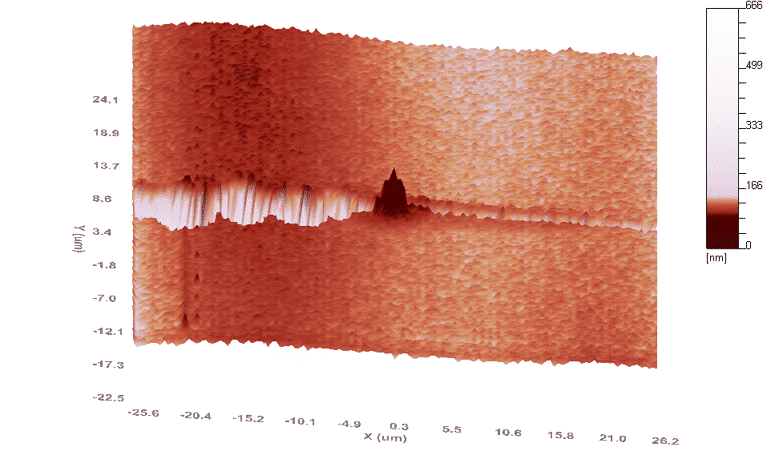

- Scanning probe microscopy (3D imaging)

- Quantitative scratch and wear test

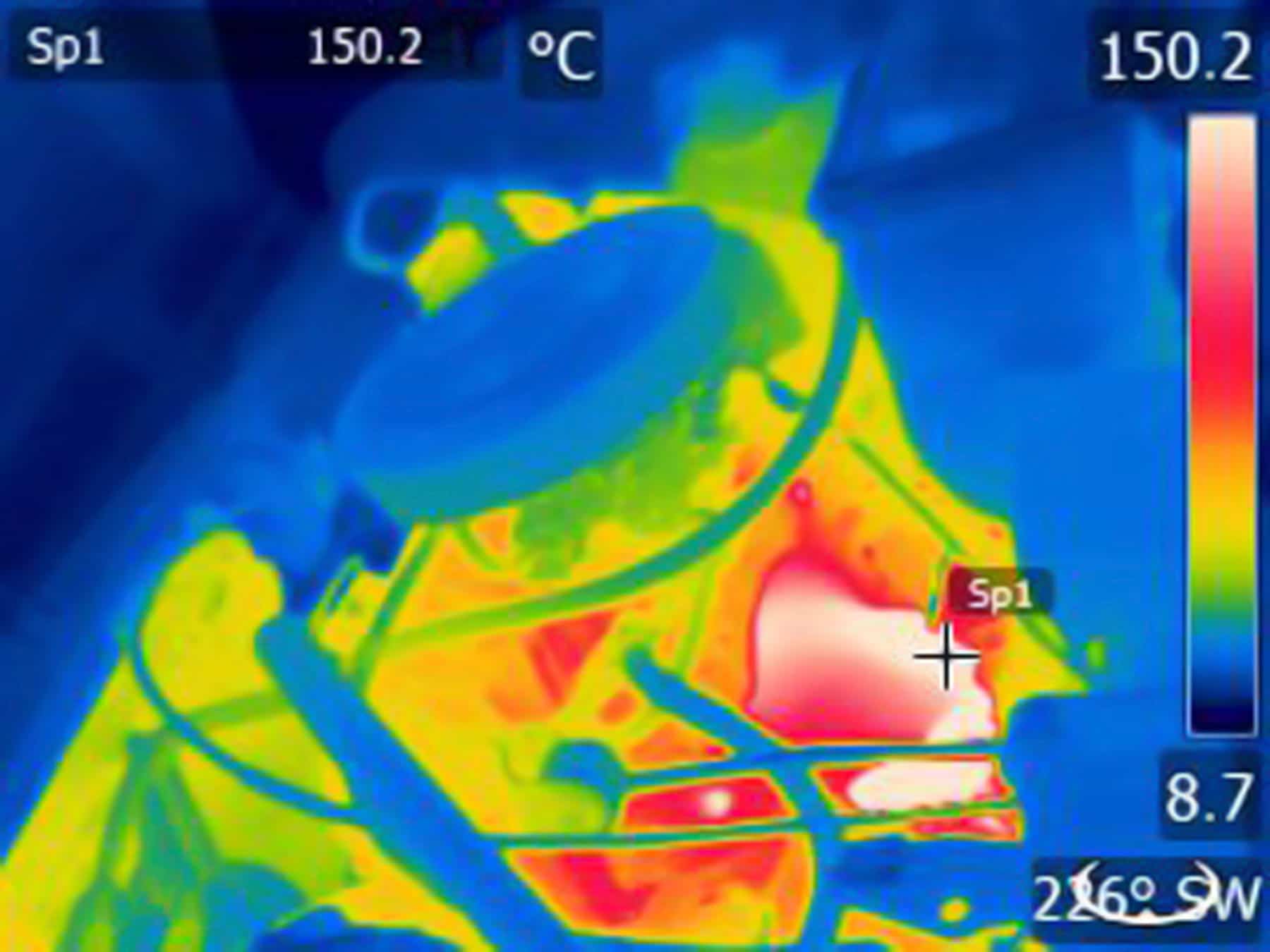

- High temperature nanoindentation test

- Industries

- Universities, research laboratories and institutes

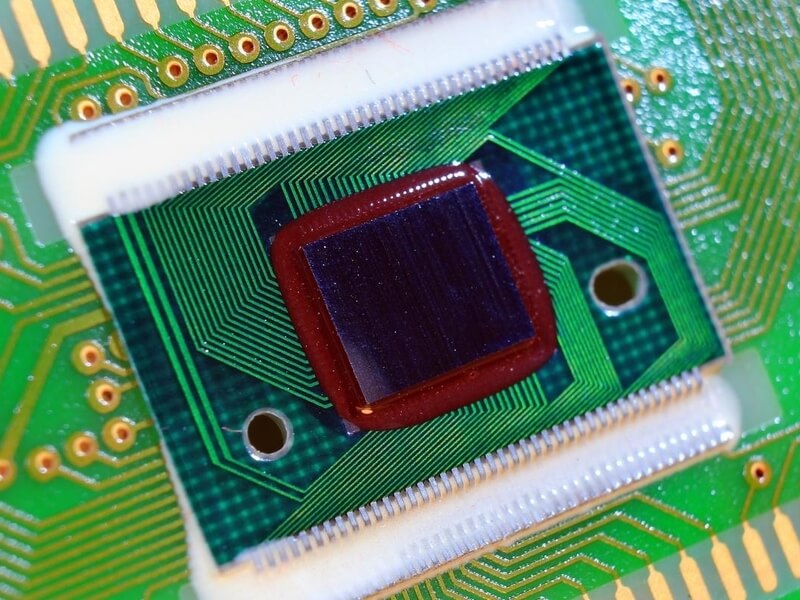

- Semiconductor industry

- Hard coatings

PVD / CVD (DLC, TiN) - PVD / CVD (DLC, TiN)

- MEMS: Micro-electromechanical systems / universal nanoscale tests

- Céramique et verre

- Ceramics and glass

Metals and alloys - Medication

- Revêtements et peintures

- Coatings and paints

- Composite materials

- Automotive and aerospace

More info on applications

- Adhesion

- Hardness

- Young module

- Scratch

Highest precision in nanoindentation

ADVANTAGES

- Easy to use and user-friendly

- Mechanical test at the nanometric scale

- Precise quantitative results

- Large variety of sample

- Electromagnetic actuator to achieve the high dynamic range in force and displacement

- High resolution optical microscope and precision XYZ motion system for viewing, positioning and targeting samples.

- Easy mount sample tray with multiple sample positions for high throughput testing.

- Modular options for testing beyond indentation for SPM imaging, scratch testing, high temperature nanoindentation measurements, dynamic testing (CSM) and high-speed testing.

- Intuitive interface for quick test setup; testing parameters can be changed with just a few mouse clicks

- Real-time experimental control, easy test protocol development and test setup.

- Full suite of InView software including ReviewData and InFocus for analyzing data and creating reports.

- Award-winning, high-speed testing for material property maps and increased statistical confidence.

- InQuest high-speed controller electronics with 100kHz data acquisition rate and 20µs time constant.

Options

InForce 1000 Actuator

InForce 50 Actuator

The InForce 50 actuator performs nanomechanical tests with forces up to 50mN. The patented electromagnetic force application ensures robust measurements and long-term force and displacement stability. Industry-leading mechanical design ensures one-degree of freedom harmonic motion so that force and displacement are controlled along a single axis. The tips are interchangeable with the entire line of InForce actuators. The InForce 50 actuator is compatible with the CSM, NanoBlitz, ProbeDMA ™, biomaterials, sample heating, scratch, wear and ISO 14577 testing options.

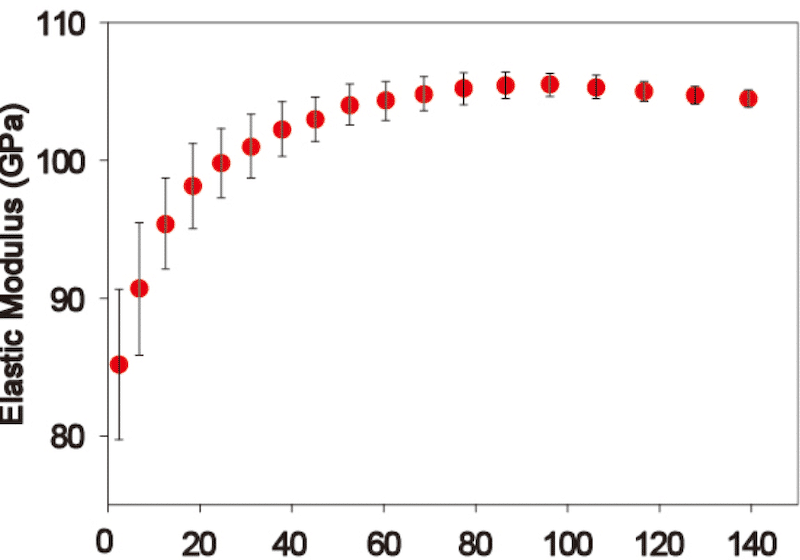

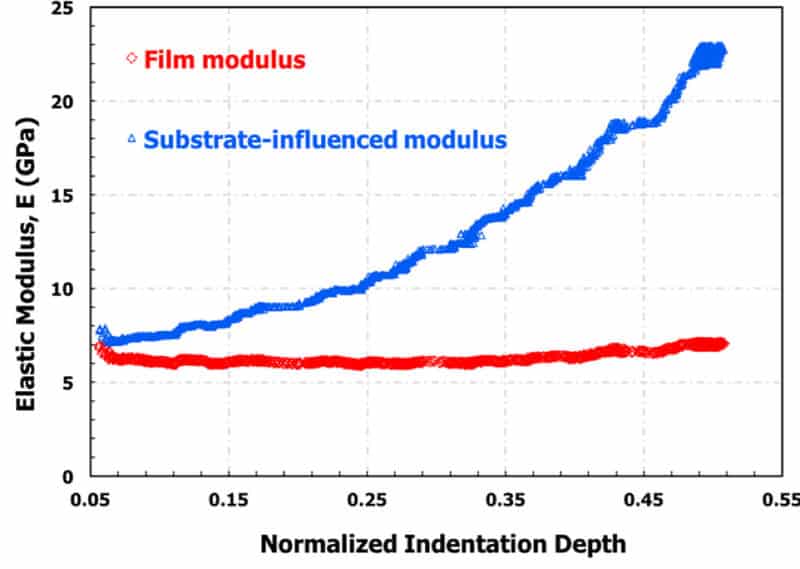

Continuous Stiffness Measurement (CSM)

Continuous stiffness measurement is used to quantify dynamic material properties, such as strain rate and frequency-induced effects. The CSM technique involves oscillating the probe during indentation to measure properties as a function of depth, force, time, or frequency. The option comes with a constant strain rate experiment that measures hardness and modulus as a function of depth or load, which is the most common test method used across academia and industry. CSM is also used for other advanced measurement options, including the ProbeDMA™ method for storage and loss modulus measurements and AccuFilm™ substrate-independent measurements. The CSM is integrated into the InQuest controller and InView software to deliver ease of use and data quality.

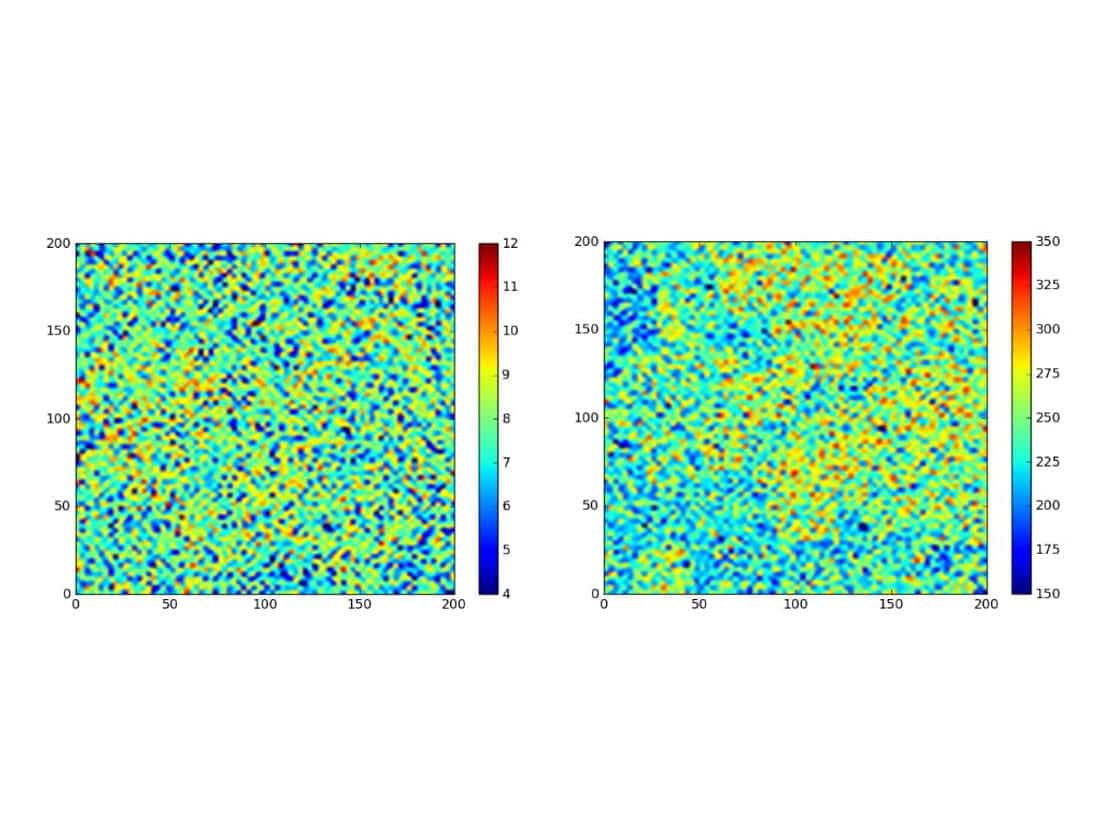

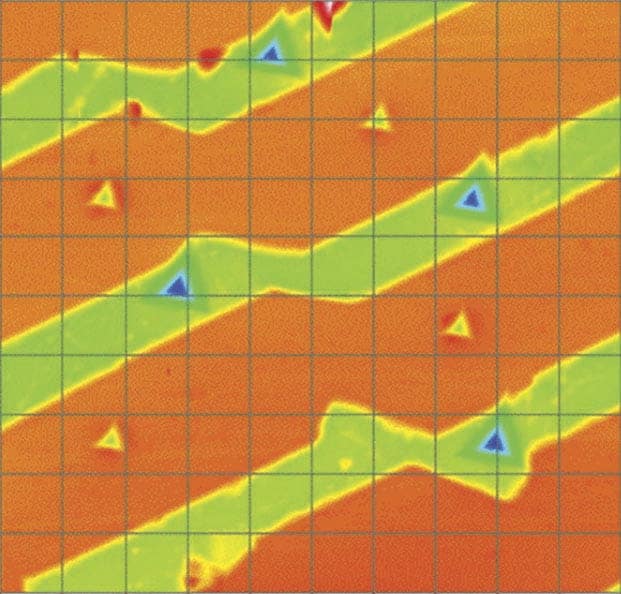

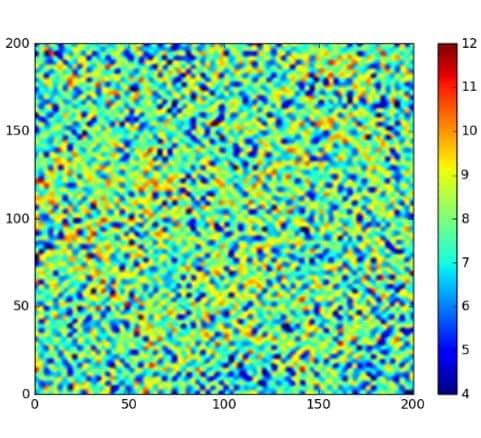

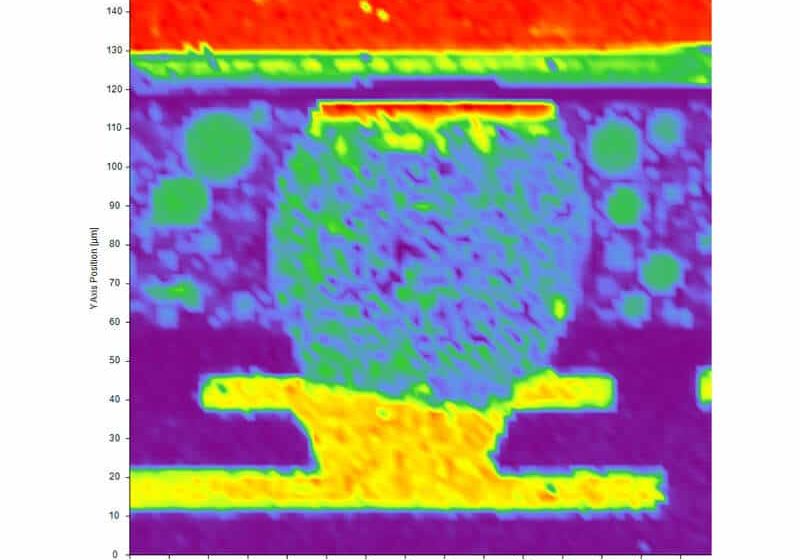

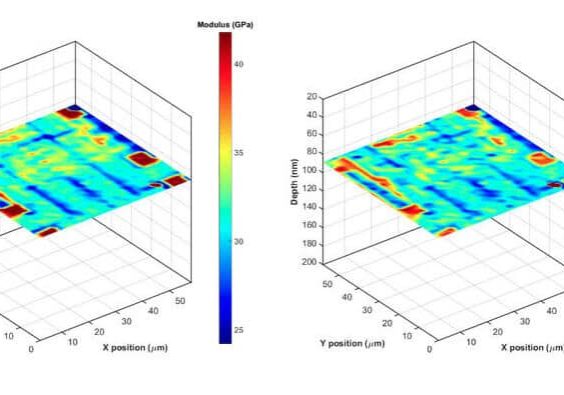

NanoBlitz 3D

NanoBlitz 3D utilizes the InForce 50 or InForce 1000 actuator and a Berkovich tip to generate 3D maps of nanomechanical properties for high-E (> 3GPa) materials. NanoBlitz performs up to 100,000 indents (300×300 array) at < 1s per indent, and provides Young’s modulus (E), hardness (H), and stiffness (S) values at a specified load for each indent in the array. The large number of tests enables increased statistical accuracy. Histogram charts show multiple phases or materials. The NanoBlitz 3D package includes visualization and data handling capabilities.

300°C Sample Heating

The 300°C sample heating option allows the sample to be placed into a chamber for uniform heating while simultaneously undergoing tests with either the InForce 1000 or InForce 50 actuators. The option includes high-precision temperature control, inert gas backfill to reduce oxidation, and cooling to remove waste heat. ProbeDMA, AccuFilm, NanoBlitz and CSM are all compatible with the sample heating option.

NanoBlitz 4D

AccuFilm™ Thin Film Method Pack

ProbeDMA™ Polymer Method Pack

The Polymer Pack provides the ability to measure the complex modulus of polymers as a function of frequency. The pack includes a flat-punch tip, a viscoelastic reference material, and a test method for evaluation of viscoelastic properties. This measurement technique is key to characterizing nanoscale polymers and polymer films that are not well-served by traditional dynamic mechanical analysis (DMA) test instruments.

Biomaterials Method Pack

The Biomaterials Method Pack provides the ability to measure the complex modulus of biomaterials with shear moduli on the order of 1kPa and utilizes Continuous Stiffness Measurement (CSM). The pack includes a flat-punch tip and a test method for evaluation of viscoelastic properties. This measurement technique is key to characterizing small scale biomaterials that are not well-served by traditional rheometer instruments.

InView Software Versions

All Nano Indenter G200X systems are powered by the standard InView software. The NanoSuite Professional version gives users access to pre-written test methods, including methods that comply with ISO 14577 standards. The InView Method Development option enables researchers to write their own InView test methods using a simple protocol. The InView software suite includes InView ReviewData and InFocus applications that make reviewing data and creating presentations easy. InView features a Simulation Mode so that users can write test methods, process and analyse data offline.

Contact us for more information on this product

Would you like an estimation ?

Additional information?

We will reply to you within 24 hours