Universal Test Machine

T150 UTM

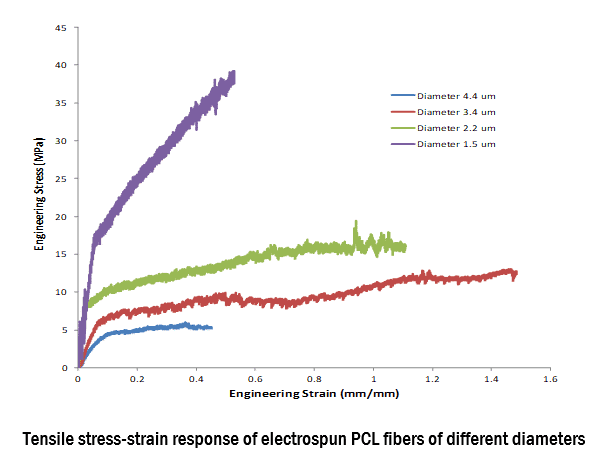

2. Simple fibers, biomaterials and polymers

3. Wide dynamic range & high resolution

Applications

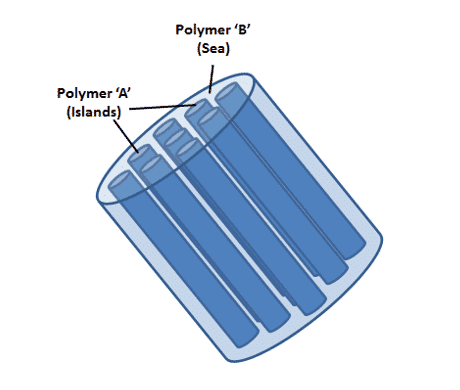

- Thin polymers, metals, composite or ceramic fibers

- Electrospun polymer nanofibers

- Polymeric films

- Biomaterials (Spider silk, soft tissue scaffolding)

textiles

- MEMS: micro-electro-mechanical systems

- Industries

- Universities, research laboratories and institutes

- MEMS: micro-electro-mechanical systems

- Fibers and textiles

- Thin polymer films

- biomedical

- Medical equipement

- Universities, research laboratories and institutes

Nanoindentation with force up to 1N

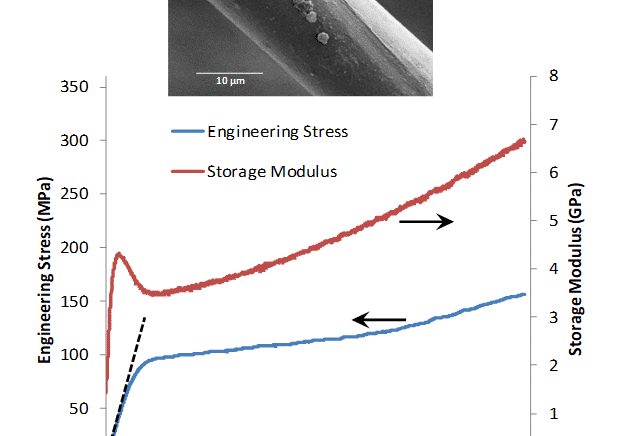

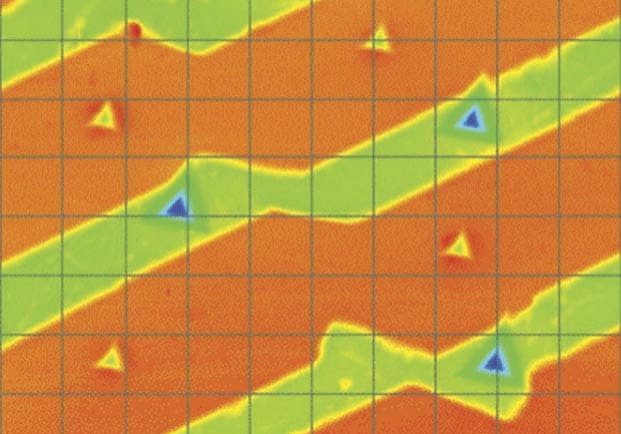

The T150 UTM has an electromagnetic transducer that functions as a force sensor, providing high sensitivity over a wide range of stresses. To facilitate the continuous determination of mechanical properties when the sample is subjected to stresses, the Continuous Dynamic Analysis (CDA) option allows a direct and precise measurement of the rigidity of the sample at each point of the experiment. CDA makes it possible to determine the storage and loss module, as well as to measure complex modules over a frequency range. T150 UTM applications include yield of compliant fibers and biomaterials, dynamic studies of fibers and biomaterials, and studies in polymer traction and compression.

ADVANTAGES

- Complete means of nanomechanical characterization

- Simple fibers, biomaterials and polymers

- Wide dynamic range & high resolution

- Electromagnetic transducer for high sensitivity over a wide range of stresses

- Dynamic characterization mode for measuring the evolution of mechanical properties with deformation

- Flexible, scalable and configurable system for a variety of applications

- Easy development of test protocols for real-time experimental control

- Meets ASTM standards

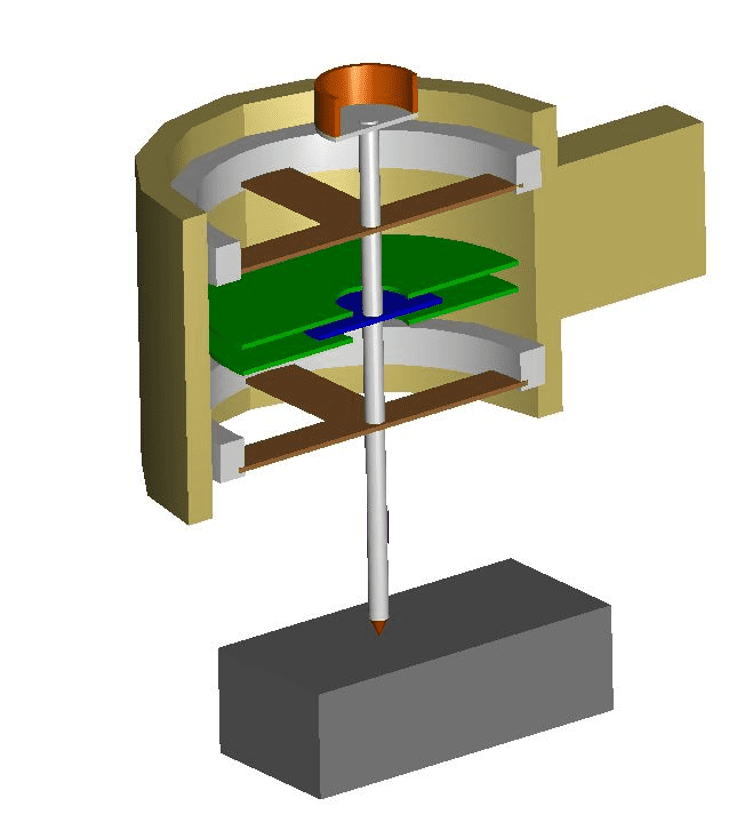

Options

The T150 UTM system has high lateral stiffness, due to a two-spring design that supports the penetrating transducer so that it is limited to one degree of freedom: the indentation axis. The movement restriction allows the behavior of the instrument to closely follow the dynamic model. The charges are applied in the micro-Newton range and the deformation measurements correspond to nanoscale extensions of the material of the sample. The nanomechanically actuated transducer head works like a load cell by sending a precise amount of current to the actuator coil so that the bottom handle of the sample stays centered. The measurement error is reduced by decoupling the load application from the displacement detection, so that the response and load mechanisms of the material measured are independent.

Continuous dynamic analysis (CDA)

The Continuous Dynamic Analysis (CDA) option offers a direct and precise measurement of the rigidity of the sample at each point of the experiment, which makes it possible to continuously determine the mechanical properties when the sample is subjected to stresses. By measuring both the amplitude and phase relationships between the load and displacement oscillations, CDA can determine the storage and loss modulus.

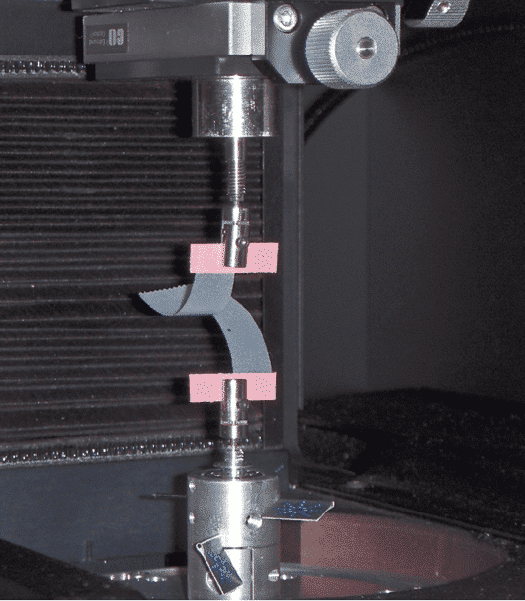

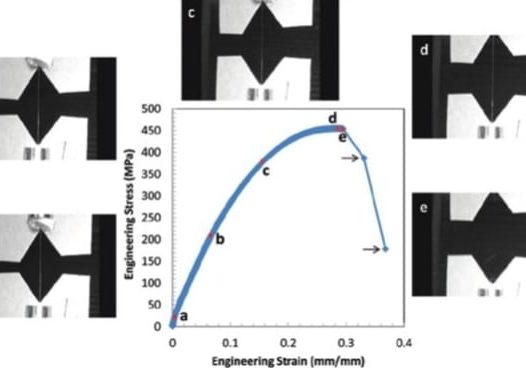

Dynamic view

Visualizing the deformation of the material and correlating it to the mechanical properties can be difficult with the characterization of the traction on the micro and nanometric scales. The T150 dynamic view option activates an external camera that monitors the deformation of single fibers during tensile testing.

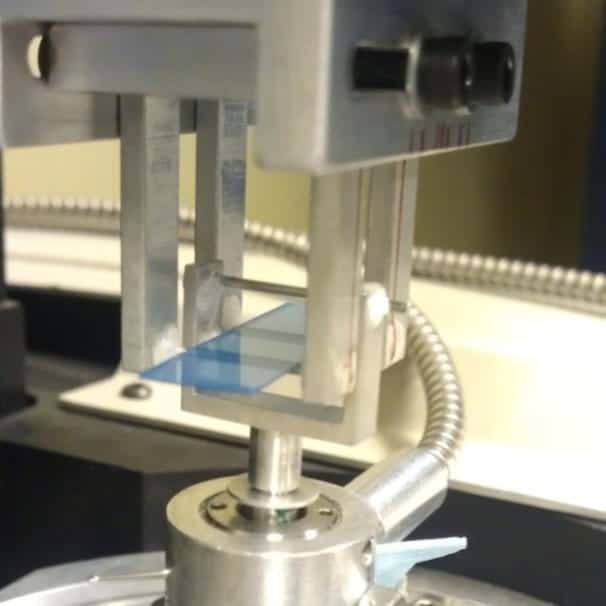

Nanoindentation conversion kit

The T150 UTM is equipped with a micro-positioner stage, a sampling guide which keeps the sample perpendicular to the direction of the applied voltage and facilitates the positioning of the upper sample point. In addition, an indentation kit including an inversion footer is available, allowing the system to be used as an indenter.

NanoSuite® software versions

All T150 UTM systems are powered by standard NanoSuite Professional software. The NanoSuite Professional version allows users to access pre-written test methods, including methods that meet ASTM standards. The NanoSuite Explorer version allows researchers to write their own NanoSuite methods using a simple protocol. The simulation mode (available with Professional and Explorer versions) allows users to write test methods and to process and analyze data offline.

Isolates the system from vibrations which can affect the results of delicate applications. The isolation cabinet is required for samples with a diameter <10 µm, long-term tests or the use of the CDA option.

Contact us for more information on this product

Would you like an estimation ?

Additional information?

We will reply to you within 24 hours